PROCESS

Maximum Effect, Minimum Means

The structural and economic advantages of concrete block define its virtues as a construction system. These advantages contribute to its common use for industrial buildings and big box retail outlets. While this investigation focuses on the possibilities of surface articulation within concrete block systems, it also relies on maintaining the structural and economic advantages inherent in the system.

Our investigation began by researching the manufacturing and construction processes. This research illuminated several conditions required to maintain these critical advantages and revealed a set of creative constraints for the design phase of the investigation.

MANUFACTURING

The affordability of concrete block is based largely on its low costs of production and installation. Since the cost of production depends on the manufacturing process, we elected to creatively work within the constraints inherent in this process.

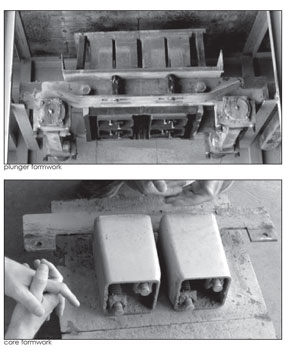

Manufacturing a typical concrete block takes place within a single machine that supplies concrete, forms the blocks and moves the blocks onto a conveyer belt. In the first step of the process, a steel plate is supplied to the bottom of a bin within the machine. The bin is then filled with zero slump concrete. A device called the plunger, which is the formwork of each block, comes from above the bin and plunges into the concrete. The block is formed and the plunger pushes the steel plate down along with the newly formed block onto a conveyer belt underneath the bin. The block then moves down the conveyor to be cured. Each cycle of this process produces two, three, or four blocks depending on the type of machine. Because the process depends on dropping the blocks out of the plunger, the block form needs to provide draft in the upward direction. This means that all projections and/or voids need to move from the outside toward the inside of the block as they move upward.